How to resolve NaN (Not a Number) Error in LS-DYNA

This article is about tips for fixing NaN errors in LS-DYNA.

NaN error means the solver fails convergence for any reasons, and it was reported in d3hsp and message file. Excessive velocities due to non-physical forces and moments could act on nodes in an unstable model.

First of all, by setting ISNAN=1 in *CONTROL_SOLUTION card, nodes with the out-of-range forces and moments can be reported in the message file. Identify the part(s) including the nodes by observing d3plot database in postprocessor, and check if warping elements in part itself or neighboring ones.

If it is difficult to find root causes, you can reduce the d3plot interval to take a close look at them. But this could be time-consuming for a large scale model. So plot the parts internal or hourglass energies in the matsum file to check abnormal increase of them. Soft materials like rubber, foam are easy to collapse when contacting with hard materials like metal due to different modulus.

After you find out the unstable part(s), there are several tips fix errors like following.

First, verify the tied contacts in model if they use unnecessarily large contact thickness, especially with soft materials. In this case, it causes non-physical contact forces to deform the tied parts too much. Use a reasonable value for SST or MST in *CONTACT_TIED or just shell thickness if without offset distance.

Second, reduce the timestep by changing TSSFAC(*CONTROL_TIMESTEP) if it does not matter calculation time. For example, TSSFAC=0.9→0.7.

Third, if you don't want to pay more cpu costs, change the element formulation like below. For shell elements, ELFORM=2↔16 or vice versa with *SECTION_SHELL. For membrane, ELFORM=5↔9. Don't forget hourglass control IHQ=4, QM=0.05(*HOURGLASS) for ELFORM=2, 5, 9 and IHQ=8, for ELFORM=16 as well. In case of solid, switch ELFORM=1↔2(*SECTION_SOLID). If use ELFORM=1, hourglass control is recommended with IHQ=6, QM=0.1 or 1.0 for soft material. If solid elements, ELFORM=2 are still the cause of error, change it to ELFORM=2, or -1, -2 to avoid shear locking.

Fourth, sometimes it is resolved by changing contact options. Try to select each soft option 1 or 2. If each option doesn't work, define two contact keywords, one for soft=1 and the other for soft=2.

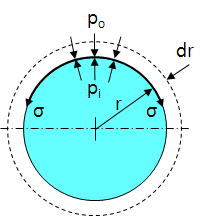

Last, mostly elements with hyperelastic material such as rubber, foam are often the case to be difficult to fix the unstable issue. In that case, make the use of *MATERIAL_ADD_EROSION to avoid large deformation before NaN error is incurred. For example, apply the failure criterion, ε1≥1.5~2.0, γmax/2≥0.5~0.7(<π/4) depending on the material.

If no answer from above, contact your local distributor for technical supports. Good luck.

댓글

댓글 쓰기